Note: This page has not been verified by our editors.

Note: This page has not been verified by our editors.

Description

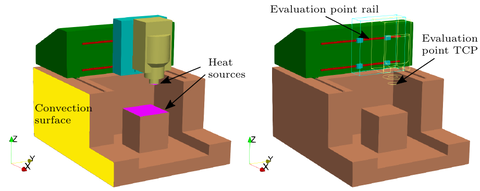

This benchmark models a machine tool composed out of two components. The "rail" part is the machine bed with a guide rail, the "slider" part moves along the rail on four carts and carries the tool. Slider and rail move relative to each other during the simulated work process. This relative movement is realized by decomposing a weighting function into a Fourier series and superposing their weighted sum, which depends on the current position of the slider. The weighted sums are then used in every time step to compute the thermal load exchanged between the two components. This approach is described in more detail in<ref=""/>. The thermal response of the system has been investigated in<ref=""/>.

The relative movement between rail and slider is modeled via a superposition of inputs and outputs. The measurement outputs have indices i=45 for the rail and i=4 for the slider and measure the temperature change in the middle of the rail and the tool center point (TCP), respectively.