Description

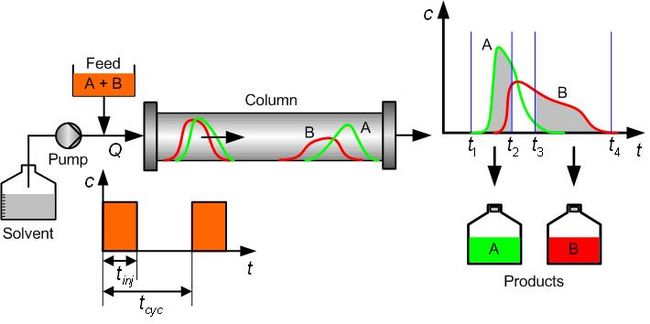

Preparative liquid chromatography as a crucial separation and purification tool has been widely employed in food, fine chemical and pharmaceutical industries. Chromatographic separation at industry scale can be operated either discontinuously or in a continuous mode. The continuous case will be discussed in the benchmark SMB, and here we focus on the discontinuous mode -- batch chromatography. The schematic diagram for the binary separation is shown in xx--CrossReference--dft--fig:bach--xx. During the injection period  , a mixture consisting of A and B is injected at the inlet of the column packed with a suitable stationary phase. With the help of the mobile phase, the feed mixture then flows through the column. Since the solutes to be separated exhibit different adsorption affinities to the stationary phase, they move at different velocities in the column, and thus separate from each other when exiting the column. At the column outlet, component A is collected between cutting points

, a mixture consisting of A and B is injected at the inlet of the column packed with a suitable stationary phase. With the help of the mobile phase, the feed mixture then flows through the column. Since the solutes to be separated exhibit different adsorption affinities to the stationary phase, they move at different velocities in the column, and thus separate from each other when exiting the column. At the column outlet, component A is collected between cutting points  and

and  , and component B is collected between

, and component B is collected between  and

and  . Here the positions of

. Here the positions of  and

and  are determined by a minimum concentration threshold that the detector can resolve. The positions of

are determined by a minimum concentration threshold that the detector can resolve. The positions of  and

and  are determined by the purity specifications imposed on the products. After the cycle period

are determined by the purity specifications imposed on the products. After the cycle period  , the injection is repeated. The feed flow-rate

, the injection is repeated. The feed flow-rate  and injection period

and injection period  are often considered as the operating variables. By properly choosing them, the process can achieve the desired performance criterion, such as production rate, while respecting the product specifications (e.g., purity, recovery yield).

are often considered as the operating variables. By properly choosing them, the process can achieve the desired performance criterion, such as production rate, while respecting the product specifications (e.g., purity, recovery yield).

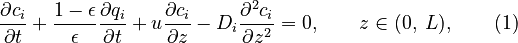

The dynamics of the batch chromatographic column can be described precisely by an axially dispersed plug-flow model with a limited mass-transfer rate characterized by a linear driving force (LDF) approximation. In this model the differential mass balance of component  (

( )

in the liquid phase can be written as:

)

in the liquid phase can be written as:

where  and

and  are the concentrations of solute

are the concentrations of solute  in the liquid and solid phases, respectively,

in the liquid and solid phases, respectively,  the interstitial liquid velocity,

the interstitial liquid velocity,  the column porosity,

the column porosity,  the time coordinate,

the time coordinate,  the axial coordinate along the column,

the axial coordinate along the column,  the column length,

the column length,  the axial dispersion coefficient and

the axial dispersion coefficient and  the Péclet number. The adsorption rate is modeled by the LDF approximation:

the Péclet number. The adsorption rate is modeled by the LDF approximation:

![\frac{\partial q_i}{\partial t} = \kappa_{i}\,(q^{Eq}_i-q_i), \qquad z\in[0,\;L],](/morwiki/images/math/c/8/8/c8881867e338ef1c9ff86be37a3998ca.png)

where  is the mass-transfer coefficient of component

is the mass-transfer coefficient of component  and

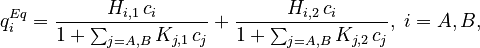

and  is the adsorption equilibrium concentration calculated by the isotherm equation for component

is the adsorption equilibrium concentration calculated by the isotherm equation for component  . Here the bi-Langmuir isotherm model is used to describe the adsorption equilibrium:

. Here the bi-Langmuir isotherm model is used to describe the adsorption equilibrium:

where  and

and  are the Henry constants, and

are the Henry constants, and  and

and  the thermodynamic coefficients.

the thermodynamic coefficients.

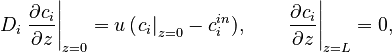

The boundary conditions for (1) are specified by the Danckwerts relations:

where  is the concentration of component

is the concentration of component  at the inlet of the column. A rectangular injection is assumed for the system and thus

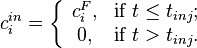

at the inlet of the column. A rectangular injection is assumed for the system and thus

Here  is the feed concentration for component

is the feed concentration for component  and

and  is the injection period. In addition, the column is assumed unloaded initially:

is the injection period. In addition, the column is assumed unloaded initially:

![c_i(t=0,z)=q_i(t=0,z)=0,\quad z\in[0,\;L],\;i=A,B.](/morwiki/images/math/b/0/a/b0aa2a0c8998935c2a0c5700b09d7887.png)

More details about the mathematical modeling for batch chromatography can be found in the literature [1].

Discretization

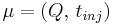

In this model, the feed volumetric flow-rate  and injection period

and injection period  are considered as the operating parameters, and denoted as the parameter

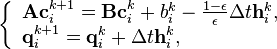

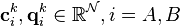

are considered as the operating parameters, and denoted as the parameter  . Using the finite volume discretization, we can get the full order model as follows,

. Using the finite volume discretization, we can get the full order model as follows,

where  are the solution vector of

are the solution vector of  and

and  at the time instance

at the time instance  respectively. The time step

respectively. The time step  is determined by the stability condition.

is determined by the stability condition.  , is time- and parameter-dependent, the boldface

, is time- and parameter-dependent, the boldface  are constant matrices. As a result, it is a nonlinear parametric system.

are constant matrices. As a result, it is a nonlinear parametric system.

Generation of ROM

The reduced order model (ROM) can be obtained by reduced bases methods, which is applicable for nonlinear parametric systems, see

Reduced Basis PMOR method. For parametrized time-dependent problems, the reduced basis can often be obtained by using POD-Greedy algorithm. Notice that the nonlinear functions  can be approximated by the empirical interpolation method [2], such that the ROM can be obtained more efficiently by the offline-online technique.

can be approximated by the empirical interpolation method [2], such that the ROM can be obtained more efficiently by the offline-online technique.

References

- ↑ G. Guiochon, A. Felinger, D. G. Shirazi, A. M. Katti, Fundamentals of Preparative and Nonlinear Chromatography, 2nd Edition, Academic Press, 2006.

- ↑ M. Barrault, Y. Maday, N.C. Nguyen, and A.T. Patera, "An 'empirical interpolation' method: application to efficient reduced-basis discretization of partial differential equations", C. R. Acad. Sci. Paris Series I, 339 (2004), 667-672.