(doi links for references) |

m (infobox string) |

||

| (17 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

[[Category:benchmark]] |

[[Category:benchmark]] |

||

| − | [[Category: |

+ | [[Category:Parametric]] |

| − | [[Category:linear |

+ | [[Category:linear]] |

| − | [[Category:first |

+ | [[Category:first differential order]] |

| − | [[Category:physical parameters]] |

||

| − | [[Category:four parameters]] |

||

[[Category:time invariant]] |

[[Category:time invariant]] |

||

| + | {{Infobox |

||

| ⚫ | |||

| + | |Title = Silicon Nitride Membrane |

||

| + | |Benchmark ID = siliconNitrideMembrane_n60020m1q2 |

||

| + | |Category = misc |

||

| + | |System-Class = AP-LTI-FOS |

||

| + | |nstates = 60020 |

||

| + | |ninputs = 1 |

||

| + | |noutputs = 2 |

||

| + | |nparameters = 2 |

||

| + | |components = A, B, C, E |

||

| + | |License = NA |

||

| + | |Creator = [[User:Feng]] |

||

| + | |Editor = |

||

| + | * [[User:Feng]] |

||

| + | * [[User:Himpe]] |

||

| + | |Zenodo-link = NA |

||

| + | }} |

||

| + | |||

| ⚫ | |||

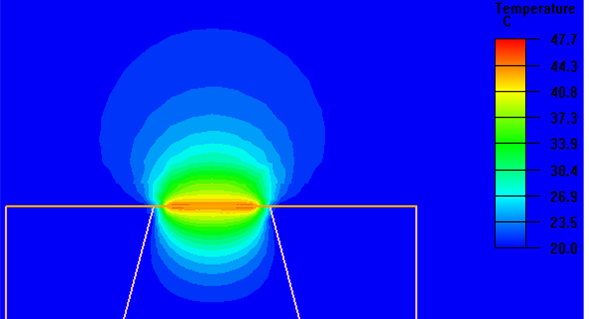

<figure id="fig:tempprof">[[File:Fig_1.png|right|frame|<caption>silicon nitride membrane temperature profile</caption>]]</figure> |

<figure id="fig:tempprof">[[File:Fig_1.png|right|frame|<caption>silicon nitride membrane temperature profile</caption>]]</figure> |

||

| + | A '''silicon nitride membrane''' ([[wikipedia:Silicon_nitride|SiN]] membrane) <ref name="bechthold10"/> can be a part of a gas sensor, |

||

| ⚫ | |||

| + | but also a part of an infra-red sensor, a microthruster, an optical filter etc. |

||

| − | a microhotplate similar to other micro-fabricated devices |

||

| + | This structure resembles a microhotplate similar to other micro-fabricated devices such as gas sensors <ref name="spannhake05"/> and infrared sources <ref name="graf04"/> (See also [[Gas_Sensor|Gas Sensor Benchmark]]). |

||

| ⚫ | |||

| + | See Fig. 1, the temperature profile for the SiN membrane. |

||

The governing heat transfer equation in the membrane is: |

The governing heat transfer equation in the membrane is: |

||

| − | <math> \nabla \cdot (\kappa \nabla T)+Q - \rho c_p \cdot \frac{\partial T}{\partial t}=0 </math> |

+ | :<math> \nabla \cdot (\kappa \nabla T)+Q - \rho c_p \cdot \frac{\partial T}{\partial t}=0 </math> |

| − | where <math>\kappa </math> is the thermal conductivity in <math>W m^{-1} K^{-1}</math>, |

+ | where <math>\kappa </math> is the thermal conductivity in <math>W m^{-1} K^{-1}</math>, |

| + | <math>c_p</math> is the specific heat capacity in <math>J kg^{-1} K^{-1}</math>, |

||

| + | <math>\rho</math> is the mass density in <math>kg m^{-3}</math> and <math>T</math> is the temperature distribution. |

||

| + | We assume a homogeneous heat generation rate over a lumped resistor: |

||

| − | <math>Q = \frac{u^2(t)}{R(T)}</math> |

+ | :<math>Q = \frac{u^2(t)}{R(T)}</math> |

with <math>Q</math> the heat generation rate per unit volume in <math>W m^{-3}</math>. |

with <math>Q</math> the heat generation rate per unit volume in <math>W m^{-3}</math>. |

||

| − | We use the initial condition <math> |

+ | We use the initial condition <math>T_0 = 273K</math>, |

| − | Dirichlet boundary condition <math> |

+ | and the Dirichlet boundary condition <math>T = 273 K</math> at the bottom of the computational domain. |

| − | the computational domain. |

||

The convection boundary condition at the top of the membrane is |

The convection boundary condition at the top of the membrane is |

||

| − | <math> |

+ | :<math> |

q=h(T-T_{air}), |

q=h(T-T_{air}), |

||

</math> |

</math> |

||

| Line 38: | Line 57: | ||

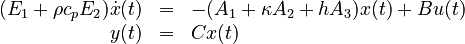

==Discretization== |

==Discretization== |

||

| − | Under the above convection boundary condition and assuming <math>T_{air}=0</math> |

+ | Under the above convection boundary condition and assuming <math>T_{air}=0</math>, |

| + | a finite element discretization of the heat transfer model leads to the parametrized system as below, |

||

| − | <math> |

+ | :<math> |

(E_0+\rho c_p \cdot E_1) \dot{T} +(A_0 +\kappa \cdot A_1 +h \cdot A_2)T = B \frac{u^2(t)}{R(T)}, \quad |

(E_0+\rho c_p \cdot E_1) \dot{T} +(A_0 +\kappa \cdot A_1 +h \cdot A_2)T = B \frac{u^2(t)}{R(T)}, \quad |

||

y=C T, |

y=C T, |

||

</math> |

</math> |

||

| − | where the volumetric heat capacity <math>\rho c_p</math>, |

+ | where the volumetric heat capacity <math>\rho c_p</math>, |

| − | <math>\kappa</math> and the heat transfer coefficient <math>h</math> between the membrane |

+ | thermal conductivity <math>\kappa</math> and the heat transfer coefficient <math>h</math> between the membrane are kept as parameters. |

| − | + | The volumetric hear capacity <math>\rho c_p</math> is the product of two independent variables, |

|

| + | i.e. the specific hear capacity <math>c_p</math> and the density <math>\rho</math>. |

||

| + | The range of interest for the four independent variables are <math>\kappa \in [2, 5]</math>, <math>c_p \in [400, 750]</math>, <math>\rho \in [3000,3200]</math> and <math> h \in [10, 12]</math> respectively. |

||

| + | The frequency range is <math>f \in [0,25]Hz</math>. |

||

| + | What is of interest is the output in time domain. |

||

| + | The interesting time interval is <math>t \in [0,0.04]s</math>. |

||

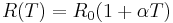

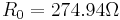

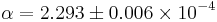

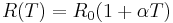

| − | Here <math>R(T)</math> is either a constant heat resistivity <math>R(T)=R_0</math>, or <math>R(T)=R_0(1+\alpha T)</math>, |

+ | Here <math>R(T)</math> is either a constant heat resistivity <math>R(T)=R_0</math>, or <math>R(T)=R_0(1+\alpha T)</math>, |

| + | which depends linearly on the temperature. |

||

| + | Here we use <math>R_0=274.94 \Omega</math> and temperature coefficient <math>\alpha=2.293 \pm 0.006 \times 10^{-4}</math>. |

||

| + | The model was created and meshed in ANSYS. It contains a constant load vector <math>B</math> corresponding to the constant input power of <math>2.49mW</math>. |

||

| + | The number of degrees of freedom is <math>n=60,020</math>. |

||

| + | The input function <math>u(t)</math> is a step function with the value <math>1</math>, |

||

| − | The input function <math>u(t)</math> is a step function with the value <math>1</math>, which disappears at the time <math>0.02s</math>. This means between <math>0s</math> and <math>0.02s</math> input is one and after that it is zero. However, be aware that <math>u(t)</math> is just a factor with which the load vector B is multiplied and which corresponds to the heating power of <math>2.49mW</math>. This means if one keeps <math>u(t)</math> as suggested above, the device is heated with <math>2.49mW</math> for the time length of 0.02s and after that the heating is turned off. If for whatever reason, one wants the heating power to be <math>5mW</math>, then <math>u(t)</math> has to be set equal to two, etc... |

||

| + | which disappears at the time <math>0.02s</math>. |

||

| ⚫ | |||

| + | This means between <math>0s</math> and <math>0.02s</math> input is one and after that it is zero. |

||

| + | However, be aware that <math>u(t)</math> is just a factor with which the load vector B is multiplied and which corresponds to the heating power of <math>2.49mW</math>. |

||

| + | This means if one keeps <math>u(t)</math> as suggested above, the device is heated with <math>2.49mW</math> for the time length of 0.02s and after that the heating is turned off. |

||

| + | If for whatever reason, one wants the heating power to be <math>5mW</math>, then <math>u(t)</math> has to be set equal to two, etc. |

||

| ⚫ | |||

==Data== |

==Data== |

||

| − | The model is generated in ANSYS. The system matrices are in <span class="plainlinks">[http://math.nist.gov/MatrixMarket/ MatrixMarket]</span> format and can be downloaded here [[Media: SiN_membrane.tgz|SiN_membrane.tgz]]. |

+ | The model is generated in ANSYS. The system matrices are in <span class="plainlinks">[http://math.nist.gov/MatrixMarket/ MatrixMarket]</span> format and can be downloaded here: [[Media: SiN_membrane.tgz|SiN_membrane.tgz]]. |

| + | |||

| + | ==Dimensions== |

||

| + | |||

| + | System structure: |

||

| + | |||

| + | :<math> |

||

| + | \begin{array}{rcl} |

||

| + | (E_1 + \rho c_p E_2)\dot{x}(t) &=& -(A_1 + \kappa A_2 + h A_3)x(t) + Bu(t) \\ |

||

| + | y(t) &=& Cx(t) |

||

| + | \end{array} |

||

| + | </math> |

||

| + | |||

| + | System dimensions: |

||

| + | |||

| + | <math>E_{1,2} \in \mathbb{R}^{60020 \times 60020}</math>, |

||

| + | <math>A_{1,2,3} \in \mathbb{R}^{60020 \times 60020}</math>, |

||

| + | <math>B \in \mathbb{R}^{60020 \times 1}</math>, |

||

| + | <math>C \in \mathbb{R}^{2 \times 60020}</math>. |

||

==References== |

==References== |

||

| − | <references |

+ | <references> |

| ⚫ | <ref name="bechthold10">T. Bechtold, D. Hohfeld, E. B. Rudnyi and M. Guenther, "<span class="plainlinks">[https://doi.org/10.1088/0960-1317/20/4/045030 Efficient extraction of thin-film thermal parameters from numerical models via parametric model order reduction]</span>", J. Micromech. Microeng. 20(4): 045030, 2010.</ref> |

||

| + | <ref name="spannhake05">J. Spannhake, O. Schulz, A. Helwig, G. Müller and T. Doll, "<span class="plainlinks">[https://doi.org/10.1109/ICSENS.2005.1597811 Design, development and operational concept of an advanced MEMS IR source for miniaturized gas sensor systems]</span>", Proc. Sensors: 762--765, 2005.</ref> |

||

| ⚫ | |||

| ⚫ | <ref name="graf04">M. Graf, D. Barrettino, S. Taschini, C. Hagleitner, A. Hierlemann and H. Baltes, "<span class="plainlinks">[https://doi.org/10.1021/ac035432h Metal oxide-based monolithic complementary metal oxide semiconductor gas sensor microsystem]</span>", Anal. Chem., 76(15): 4437--4445, 2004.</ref> |

||

| + | |||

| + | </references> |

||

| + | |||

| ⚫ | |||

'' [[User:Feng|Lihong Feng]] '' |

'' [[User:Feng|Lihong Feng]] '' |

||

| − | [http:// |

+ | [http://www.igs.uni-rostock.de/mitarbeiter/tamara-bechtold/ Tamara Bechtold] |

Latest revision as of 10:40, 30 November 2023

| Background | |

|---|---|

| Benchmark ID |

siliconNitrideMembrane_n60020m1q2 |

| Category |

misc |

| System-Class |

AP-LTI-FOS |

| Parameters | |

| nstates |

60020

|

| ninputs |

1 |

| noutputs |

2 |

| nparameters |

2 |

| components |

A, B, C, E |

| Copyright | |

| License |

NA |

| Creator | |

| Editor | |

| Location | |

|

NA | |

Description

A silicon nitride membrane (SiN membrane) [1] can be a part of a gas sensor, but also a part of an infra-red sensor, a microthruster, an optical filter etc. This structure resembles a microhotplate similar to other micro-fabricated devices such as gas sensors [2] and infrared sources [3] (See also Gas Sensor Benchmark). See Fig. 1, the temperature profile for the SiN membrane.

The governing heat transfer equation in the membrane is:

where  is the thermal conductivity in

is the thermal conductivity in  ,

,

is the specific heat capacity in

is the specific heat capacity in  ,

,

is the mass density in

is the mass density in  and

and  is the temperature distribution.

We assume a homogeneous heat generation rate over a lumped resistor:

is the temperature distribution.

We assume a homogeneous heat generation rate over a lumped resistor:

with  the heat generation rate per unit volume in

the heat generation rate per unit volume in  .

We use the initial condition

.

We use the initial condition  ,

and the Dirichlet boundary condition

,

and the Dirichlet boundary condition  at the bottom of the computational domain.

at the bottom of the computational domain.

The convection boundary condition at the top of the membrane is

where  is the heat transfer coefficient between the membrane and the ambient air in

is the heat transfer coefficient between the membrane and the ambient air in  .

.

Discretization

Under the above convection boundary condition and assuming  ,

a finite element discretization of the heat transfer model leads to the parametrized system as below,

,

a finite element discretization of the heat transfer model leads to the parametrized system as below,

where the volumetric heat capacity  ,

thermal conductivity

,

thermal conductivity  and the heat transfer coefficient

and the heat transfer coefficient  between the membrane are kept as parameters.

The volumetric hear capacity

between the membrane are kept as parameters.

The volumetric hear capacity  is the product of two independent variables,

i.e. the specific hear capacity

is the product of two independent variables,

i.e. the specific hear capacity  and the density

and the density  .

The range of interest for the four independent variables are

.

The range of interest for the four independent variables are ![\kappa \in [2, 5]](/morwiki/images/math/c/4/0/c4006e8fec84878cf9013e084f470889.png) ,

, ![c_p \in [400, 750]](/morwiki/images/math/8/d/a/8daae83528f36a960c1f0a9c20228e10.png) ,

, ![\rho \in [3000,3200]](/morwiki/images/math/0/3/4/03450d9dc5111d1713c04580ceb8b308.png) and

and ![h \in [10, 12]](/morwiki/images/math/b/5/7/b574d329148c4798673036209b01fe86.png) respectively.

The frequency range is

respectively.

The frequency range is ![f \in [0,25]Hz](/morwiki/images/math/e/1/6/e1649ce4f8b21c6a673bdeb8c9b45eb2.png) .

What is of interest is the output in time domain.

The interesting time interval is

.

What is of interest is the output in time domain.

The interesting time interval is ![t \in [0,0.04]s](/morwiki/images/math/1/d/1/1d18fb0d095a173bc242f892cca43db1.png) .

.

Here  is either a constant heat resistivity

is either a constant heat resistivity  , or

, or  ,

which depends linearly on the temperature.

Here we use

,

which depends linearly on the temperature.

Here we use  and temperature coefficient

and temperature coefficient  .

The model was created and meshed in ANSYS. It contains a constant load vector

.

The model was created and meshed in ANSYS. It contains a constant load vector  corresponding to the constant input power of

corresponding to the constant input power of  .

The number of degrees of freedom is

.

The number of degrees of freedom is  .

.

The input function  is a step function with the value

is a step function with the value  ,

which disappears at the time

,

which disappears at the time  .

This means between

.

This means between  and

and  input is one and after that it is zero.

However, be aware that

input is one and after that it is zero.

However, be aware that  is just a factor with which the load vector B is multiplied and which corresponds to the heating power of

is just a factor with which the load vector B is multiplied and which corresponds to the heating power of  .

This means if one keeps

.

This means if one keeps  as suggested above, the device is heated with

as suggested above, the device is heated with  for the time length of 0.02s and after that the heating is turned off.

If for whatever reason, one wants the heating power to be

for the time length of 0.02s and after that the heating is turned off.

If for whatever reason, one wants the heating power to be  , then

, then  has to be set equal to two, etc.

When

has to be set equal to two, etc.

When  , it is a function of the state vector

, it is a function of the state vector  and hence, the system has non-linear input (It is also called a weakly nonlinear system.).

and hence, the system has non-linear input (It is also called a weakly nonlinear system.).

Data

The model is generated in ANSYS. The system matrices are in MatrixMarket format and can be downloaded here: SiN_membrane.tgz.

Dimensions

System structure:

System dimensions:

,

,

,

,

,

,

.

.

References

- ↑ T. Bechtold, D. Hohfeld, E. B. Rudnyi and M. Guenther, "Efficient extraction of thin-film thermal parameters from numerical models via parametric model order reduction", J. Micromech. Microeng. 20(4): 045030, 2010.

- ↑ J. Spannhake, O. Schulz, A. Helwig, G. Müller and T. Doll, "Design, development and operational concept of an advanced MEMS IR source for miniaturized gas sensor systems", Proc. Sensors: 762--765, 2005.

- ↑ M. Graf, D. Barrettino, S. Taschini, C. Hagleitner, A. Hierlemann and H. Baltes, "Metal oxide-based monolithic complementary metal oxide semiconductor gas sensor microsystem", Anal. Chem., 76(15): 4437--4445, 2004.