Note: This page has not been verified by our editors.

Note: This page has not been verified by our editors.

Description

Motivation

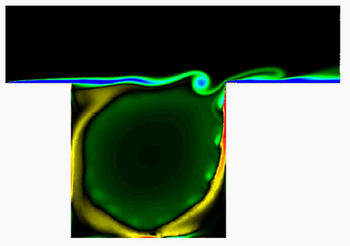

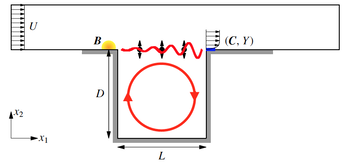

This benchmark considers a fluid-flow configuration. It consists of a two-dimensional open square cavity geometry flow problem where air flows from left to right. Such a configuration is described in details in the original work of [1] and also (with a more dynamical system view point) in [2], and illustrated on the xx--CrossReference--dft--fig:cavity--xx and xx--CrossReference--dft--fig:cavityScheme--xx.

For simulation purpose, the phenomena modeled by Navier and Stokes equations, is spatially discretized along a mesh composed of  triangles, corresponding to

triangles, corresponding to  degrees of freedom for the velocity variables along the

degrees of freedom for the velocity variables along the  and

and  axis. After linearization around three fixed points for varying Reynolds numbers

axis. After linearization around three fixed points for varying Reynolds numbers  three dynamical models

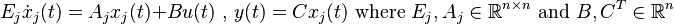

three dynamical models  can be described as a DAE realisation of order

can be described as a DAE realisation of order  given as (matrices, about 100Mo each, can be provided under request to Charles Poussot-Vassal )

given as (matrices, about 100Mo each, can be provided under request to Charles Poussot-Vassal )

where the input  is the vertical pressure actuator located upstream of the cavity and the output

is the vertical pressure actuator located upstream of the cavity and the output  is a shear stress sensor, located downstream of the cavity. In this particular case, the parameter is the Reynolds number

is a shear stress sensor, located downstream of the cavity. In this particular case, the parameter is the Reynolds number  . The transfer functions read

. The transfer functions read

In \cite{PoussotLPVS:2015}, the IRKA approach (being a realization based  -oriented reduction method) is used to sequentially approximate each realization with a low dimensional one. Then, the interpolation along the parameter is done in a second step by interpolating each coefficients in the canonical basis of the obtained realization.

-oriented reduction method) is used to sequentially approximate each realization with a low dimensional one. Then, the interpolation along the parameter is done in a second step by interpolating each coefficients in the canonical basis of the obtained realization.

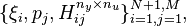

Here instead, we suggest the parametric Loewner framework is applied. First, the frequency response of the three configurations for $N=200$ logarithmically spaced frequencies $\{z_k\}_{k=1}^N=\{\imath \omega_{\overline k},-\imath \omega_{\overline k}\}_{k=1}^{N/2}$ are first computed. Then, ten intermediate configurations between each Reynolds numbers $Re=\{4000,5250,6000\}$ are constructed by linear interpolation. We obtain $\{z_k\}_{k=1}^{N=200}$, $\{p_l\}_{l=1}^{N=31}$ and thus $\Phi \in \IC^{200 \times 31}$. Our objective is to come up with a parametrized linear model that is able to faithfully reproduce the original transfer data on a particular range of frequencies as well as on a target parameter range.

Considered data

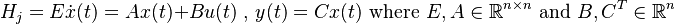

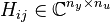

The benchmark contains a set of complex-domain reponses provided at varying real frozen Reynolds parametric values. The numerical values data as inspired (but slightly modified) from the reference paper given below and are provided as Matlab data. More specifically, This benchmark contains a set of complex-domain/parametric(real)-domain input-output data computed from a high dimensional linear descriptor model given as (where  ):

):

and which matrices have been obtained by linearizing the Navier and Stokes equations at frozen Reynolds numbers, from a high fidelity simulator.

The data provided in this use-case are given as the triple:

where  represents the transfer from

represents the transfer from  input signal (upward cavity pressure) to

input signal (upward cavity pressure) to  measurement output (downward cavity pressure), evaluated at varying complex values

measurement output (downward cavity pressure), evaluated at varying complex values  and

and  , for

, for  .

Specifically, the frequencies are between 0.1Hz until 42.1Hz in steps of 0.1Hz.

.

Specifically, the frequencies are between 0.1Hz until 42.1Hz in steps of 0.1Hz.

Origin

Collaboration between ONERA DTIS (dynamical systems and information departement) and DAAA (Fluid mechanics departement). The data come from a fluid simulator (coded in FreeFem++). The model is constructed by D. Sipp and post-processing was performed jointly by P. Vuillemin and C. Poussot-Vassal.

Data

Description

Objective

Citation

To cite this benchmark, use the following references:

- For the benchmark itself and its data:

- The MORwiki Community, Fluid Flow Linearized Open Cavity Model. MORwiki - Model Order Reduction Wiki, 2021. https://morwiki.mpi-magdeburg.mpg.de/morwiki/index.php/Fluid_Flow_Linearized_Open_Cavity_Model

- For the background on the benchmark with a dynamical and control engineering point of view:

@inproceedings{PoussotLPVS:2015,

author = {C. Poussot-Vassal and D. Sipp},

title = {Parametric reduced order dynamical model construction of a fluid flow control problem},

booktitle = {Proceedings of the 1st IFAC Workshop on Linear Parameter Varying Systems},

address = {Grenoble, France},

month = {October},

year = {2015},

pages = {133-138},

}

- For the background on the benchmark with a fluid-flow point of view:

@article{Barbagallo:2008,

author = {A. Barbagallo and D. Sipp and P.J. Schmid},

journal = {Journal of Fluid Mechanics},

pages = {1-50},

title = {Closed-loop control of an open cavity flow using reduced-order models},

volume = {641},

year = {2008}

}

References

- ↑ A. Barbagallo and D. Sipp and P.J. Schmid, "Closed-loop control of an open cavity flow using reduced-order models", Journal of Fluid Mechanics, vol. 641, pp. 1-50

- ↑ C. Poussot-Vassal and D. Sipp, "Parametric reduced order dynamical model construction of a fluid flow control problem", in Proceedings of the 1st IFAC Workshop on Linear Parameter Varying Systems (LPVS), Grenoble, France, 2015, pp. 133-138.