| Line 13: | Line 13: | ||

==Description== |

==Description== |

||

| + | <figure id="fig:cad"> |

||

| ⚫ | |||

| + | [[File:Staender_Geom_white.jpg|thumb|right|120px|CAD Geometry]] |

||

| + | </figure> |

||

| + | |||

| ⚫ | The '''vertical stand''' (see <xr id="fig:cad"/>) represents a structural part of a machine tool. On one of its surfaces a pair of guide rails is located. Caused by a machining process a tool slide is moving on these rails. The machining process produces a certain amount of heat which is transported through the structure into the '''vertical stand'''. This heat source is considered to be a temperature input at the guide rails. This transfered heat amount leads to deformations within the device induced by the prevailed temperature field denoted by <math> x </math>. The evolution of this field is modeled by the heat equation |

||

:<math> |

:<math> |

||

| Line 51: | Line 55: | ||

==Acknowledgement & Origin== |

==Acknowledgement & Origin== |

||

| − | The base model was developed <ref name="GalGM15" /> in the [http://transregio96.de Collaborative Research Centre Transregio 96] ''Thermo-Energetic Design of Machine Tools'' funded by the [http://www.dfg.de/en/index.jsp Deutsche Forschungsgemeinschaft] . |

+ | The base model was developed <ref name="GalGM11" />, <ref name="GalGM15" /> in the [http://transregio96.de Collaborative Research Centre Transregio 96] ''Thermo-Energetic Design of Machine Tools'' funded by the [http://www.dfg.de/en/index.jsp Deutsche Forschungsgemeinschaft] . |

| − | The following specific model representations have been developed and investigated in <ref name="morLanSB14" />. |

+ | The following specific model representations have been developed and investigated in <ref name="morLanSB14" />, <ref name="LanSB15" />. |

==Data== |

==Data== |

||

Revision as of 12:18, 13 March 2018

Note: This page has not been verified by our editors.

Note: This page has not been verified by our editors.

1 Description

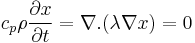

The vertical stand (see xx--CrossReference--dft--fig:cad--xx) represents a structural part of a machine tool. On one of its surfaces a pair of guide rails is located. Caused by a machining process a tool slide is moving on these rails. The machining process produces a certain amount of heat which is transported through the structure into the vertical stand. This heat source is considered to be a temperature input at the guide rails. This transfered heat amount leads to deformations within the device induced by the prevailed temperature field denoted by  . The evolution of this field is modeled by the heat equation

. The evolution of this field is modeled by the heat equation

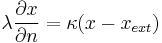

with the boundary conditions

on

on  (surface where the tool slide is moving on the guide rails),

(surface where the tool slide is moving on the guide rails),

describing the heat transfer between the tool slide and the vertical stand. The heat transfer to the ambience is given by the Robin-type boundary condition

on

on  (remaining boundaries),

(remaining boundaries),

which describes t.

Width ( direction):

direction):  ,

,

Height ( direction):

direction):  ,

,

Depth ( direction):

direction):

The heat load  induced by the slide and the external temperature

induced by the slide and the external temperature  serve as the input

serve as the input  of the corresponding state-space system.

of the corresponding state-space system.

The motion of the tool slide and the associated variation of the affected input boundary are modeled by two different system representations.

1.1 Switched linear system

1.2 Linear Parameter-varying system

2 Acknowledgement & Origin

The base model was developed [1], [2] in the Collaborative Research Centre Transregio 96 Thermo-Energetic Design of Machine Tools funded by the Deutsche Forschungsgemeinschaft .

The following specific model representations have been developed and investigated in [3], [4].

3 Data

3.1 Switched System Data

3.2 Parametric System Data

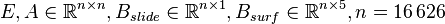

The data file Data_VertStand.tar.gz contains a MAT_File matrices.mat which consists of the matrices

in sparse format and a file with the coordinates of the mesh nodes called coord.txt.

Here  consists of all nodes located on the guide rails.

consists of all nodes located on the guide rails.

In order to get a parameter dependent matrix

one has to pick the "active" nodes (nodes hit by tool carriage) at vertical position

one has to pick the "active" nodes (nodes hit by tool carriage) at vertical position  .

The "active" nodes are in the interval of

.

The "active" nodes are in the interval of ![[\mu-\frac{d}{2},\mu+\frac{d}{2}]](/morwiki/images/math/a/7/1/a71f92fd4be99066106491025fe32ad6.png) , where

, where  is the heigth of the slide.

is the heigth of the slide.

The file coord.txt provided in Data_VertStand.tar.gz includes a column with indices followed by three additional columns containing the spatial coordinates  of the corresponding nodes.

of the corresponding nodes.

The matrix  describes the locations where the external temperatures act on.

The first column is responsible for the input of the temperature at the clamped bottom slice of the structure.

Column 2 describes the ... part of the stand. Columns 3 to 5 describe different thresholds with respect to the height of ambient air temperature.

The third column includes the nodes of the lower third

describes the locations where the external temperatures act on.

The first column is responsible for the input of the temperature at the clamped bottom slice of the structure.

Column 2 describes the ... part of the stand. Columns 3 to 5 describe different thresholds with respect to the height of ambient air temperature.

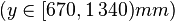

The third column includes the nodes of the lower third  of the stand.

In column 4 all nodes of the middle third

of the stand.

In column 4 all nodes of the middle third  of the geometry are contained

and the fifth column of

of the geometry are contained

and the fifth column of  includes the missing upper

includes the missing upper ![(y\in[1\,340,2\,010]mm)](/morwiki/images/math/8/f/7/8f7ee61fb31ab9462369fff516b9d051.png) part.

part.

4 Citation

To cite this benchmark, use the following references:

- For the benchmark itself and its data:

- The MORwiki Community. Vertical Stand. MORwiki - Model Order Reduction Wiki, 2018. http://modelreduction.org/index.php/Vertical_Stand

@MISC{morwiki_vertstand,

author = {The {MORwiki} Community},

title = {Vertical Stand},

howpublished = {{MORwiki} -- Model Order Reduction Wiki},

url = {http://modelreduction.org/index.php/Vertical_Stand},

year = {2014}

}

- For the background on the benchmark:

@Article{morLanSB14,

author = {Lang, Norman and Saak, Jens and Benner, Peter},

title = {Model Order Reduction for Systems with Moving Loads},

journal = {at-Automatisierungstechnik},

year = 2014,

volume = 62,

number = 7,

pages = {512--522},

month = {June},

publisher = {deGruyter},

doi = {10.1515/auto-2014-1095}

}

5 References

- ↑ Cite error: Invalid

<ref>tag; no text was provided for refs namedGalGM11 - ↑ A. Galant, K. Großmann and A. Mühl, Thermo-Elastic Simulation of Entire Machine Tool , In: Thermo Energetic Design of Machine Tools, Lecture Notes in Production Engineering, 69-84, 2015

- ↑ N. Lang and J. Saak and P. Benner, Model Order Reduction for Systems with Moving Loads , in De Gruyter Oldenbourg: at-Automatisierungstechnik, Volume 62, Issue 7, Pages 512-522, 2014

- ↑ N. Lang, J. Saak and P. Benner, Model Order Reduction for Thermo-Elastic Assembly Group Models , In: Thermo Energetic Design of Machine Tools, Lecture Notes in Production Engineering, 85-92, 2015