| Line 55: | Line 55: | ||

==Acknowledgement & Origin== |

==Acknowledgement & Origin== |

||

| − | This model was developed and investigated in the [http://transregio96.de collaborative research cluster Transregio 96] ''Thermo-Energetic Design of Machine Tools'' funded by the [http://www.dfg.de/en/index.jsp Deutsche Forschungsgemeinschaft] . |

+ | This model was developed and investigated<ref name="LanSB15">,<ref name="GalGM15"> in the [http://transregio96.de collaborative research cluster Transregio 96] ''Thermo-Energetic Design of Machine Tools'' funded by the [http://www.dfg.de/en/index.jsp Deutsche Forschungsgemeinschaft] . |

==Data== |

==Data== |

||

Revision as of 15:44, 7 March 2018

1 Description

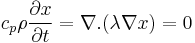

The vertical stand represents a structural part of a machine tool. On one of its surfaces there are guide rails located. On these rails a tool slide is moving due to the machining process the slide has to perform by the machine tool on top. The machining process produces a certain amount of heat which is transported through the structure into the vertical stand. This heat source is considered to be a temperature input at the guide rails. This transfered heat amount leads to deformations within the device induced by the prevailed temperature field denoted by  . The evolution of this field is modeled by the heat equation

. The evolution of this field is modeled by the heat equation

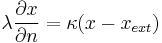

with the boundary conditions

on

on  (surface where the tool slide is moving on the guide rails),

(surface where the tool slide is moving on the guide rails),

describing the heat transfer between the tool slide and the vertical stand and

on

on  (remaining boundaries),

(remaining boundaries),

which describes the heat transfer to the ambience.

The heat load  induced by the slide and the external temperature

induced by the slide and the external temperature  serve as the input

serve as the input  of the corresponding state-space system.

of the corresponding state-space system.

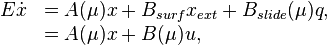

The position of the moving slide has been included into the system as a parameter dependency  . Due to this motion the boundary

. Due to this motion the boundary  , where the input acts on the system is varying. Thus, the system matrix

, where the input acts on the system is varying. Thus, the system matrix  and the input matrix

and the input matrix  become parameter dependent.

become parameter dependent.

Finally, the system describing the heat evolution induced by the moving heat source is given by:

where

The quantity  can be assumed as a vector including different ambient temperatures corresponding to different locations of the geometry.

can be assumed as a vector including different ambient temperatures corresponding to different locations of the geometry.

2 Acknowledgement & Origin

This model was developed and investigatedCite error: Closing </ref> missing for <ref> tag

</references>

- ↑ Thermo-Elastic Simulation of Entire Machine Tool , In: Thermo Energetic Design of Machine Tools, Lecture Notes in Production Engineering, 69-84, 2015

![\begin{array}{lll}

B(\mu)&=[B_{surf}, B_{slide}(\mu)],\\

u&=[x_{ext}^T,q]^T.\\

\end{array}](/morwiki/images/math/4/b/0/4b06d8ab772cfd529264662f29fcdf3a.png)