(Added Convection Benchmark (TEMP)) |

(Added Convection Benchmark) |

||

| Line 1: | Line 1: | ||

{{preliminary}} <!-- Do not remove --> |

{{preliminary}} <!-- Do not remove --> |

||

| + | {{DISPLAYTITLE:Convective Thermal Flow Problems}} |

||

[[Category:benchmark]] |

[[Category:benchmark]] |

||

| Line 7: | Line 8: | ||

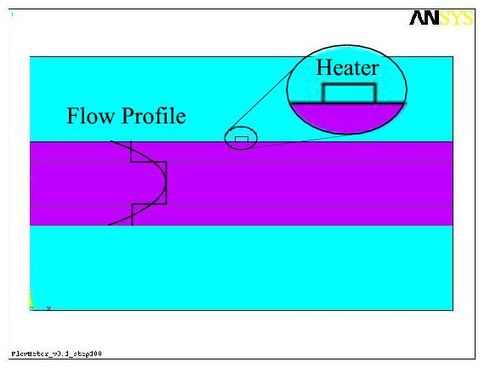

<figure id="fig1">[[File:Convection1.jpg|490px|thumb|right|Figure 1: Convective heat flow example: 2D anemometer model]]</figure> |

<figure id="fig1">[[File:Convection1.jpg|490px|thumb|right|Figure 1: Convective heat flow example: 2D anemometer model]]</figure> |

||

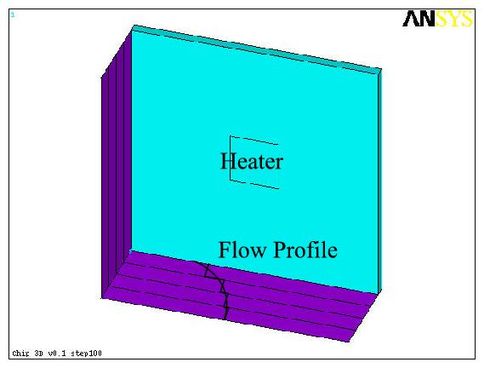

<figure id="fig1">[[File:Convection2.jpg|490px|thumb|right|Figure 2: Convective heat flow example: 3D cooling structure]]</figure> |

<figure id="fig1">[[File:Convection2.jpg|490px|thumb|right|Figure 2: Convective heat flow example: 3D cooling structure]]</figure> |

||

| − | |||

| − | Convective Thermal Flow Problems (38867) |

||

Many thermal problems require simulation of heat exchange between a solid body and a fluid flow. |

Many thermal problems require simulation of heat exchange between a solid body and a fluid flow. |

||

| Line 24: | Line 23: | ||

Two different designs are tested: a 2D model of an anemometer-like structure mainly consisting of a tube and a small heat source (Fig. 1) <ref name="ernst2001"/>. |

Two different designs are tested: a 2D model of an anemometer-like structure mainly consisting of a tube and a small heat source (Fig. 1) <ref name="ernst2001"/>. |

||

The solid model has been generated and meshed in [http://www.ansys.com ANSYS]. |

The solid model has been generated and meshed in [http://www.ansys.com ANSYS]. |

||

| − | Triangular PLANE55 elements have been used for meshing and discretizing by the finite element method, resulting in |

+ | Triangular PLANE55 elements have been used for meshing and discretizing by the finite element method, resulting in 19282 elements and 9710 nodes. |

The second design is a 3D model of a chip cooled by forced convection (Fig. 2) <ref name="harper1997"/>. |

The second design is a 3D model of a chip cooled by forced convection (Fig. 2) <ref name="harper1997"/>. |

||

| − | In this case the tetrahedral element type SOLID70 was used, resulting in |

+ | In this case the tetrahedral element type SOLID70 was used, resulting in 107989 elements and 20542 nodes. |

Since the implementation of the convective term in ANSYS does not allow for definition of the fluid speed on a per element, but on a per region basis, the flow profile has to be approximated by piece-wise step functions. |

Since the implementation of the convective term in ANSYS does not allow for definition of the fluid speed on a per element, but on a per region basis, the flow profile has to be approximated by piece-wise step functions. |

||

The approximation used for this benchmarks is shown in Figure 1. |

The approximation used for this benchmarks is shown in Figure 1. |

||

| Line 37: | Line 36: | ||

==Origin== |

==Origin== |

||

| − | This benchmark is part of the '''Oberwolfach Benchmark Collection'''<ref name="korvink2005"/>. |

+ | This benchmark is part of the '''Oberwolfach Benchmark Collection'''<ref name="korvink2005"/>; No. 38867, see <ref name="moosmann2005"/>. |

==Data== |

==Data== |

||

| Line 45: | Line 44: | ||

The system matrices have been extracted from ANSYS models by means of mor4fem. |

The system matrices have been extracted from ANSYS models by means of mor4fem. |

||

| + | {| class="wikitable" style="margin: auto;" |

||

| + | |+ style="caption-side:bottom;"|''Table 1: Output nodes for the two models.'' |

||

| + | |- |

||

| + | |Model |

||

| + | |Number |

||

| + | |Code |

||

| + | |Comment |

||

| + | |- |

||

| + | |Flow Meter |

||

| + | |1 |

||

| + | |out1 |

||

| + | |outlet position |

||

| + | |- |

||

| + | | |

||

| + | |2 |

||

| + | |out2 |

||

| + | |outlet position |

||

| + | |- |

||

| + | | |

||

| + | |3 |

||

| + | |SenL |

||

| + | |left sensor position |

||

| + | |- |

||

| + | | |

||

| + | |4 |

||

| + | |Heater |

||

| + | |within the heater |

||

| + | |- |

||

| + | | |

||

| + | |5 |

||

| + | |SenR |

||

| + | |right sensor position |

||

| + | |- |

||

| + | |Cooling Structure |

||

| + | |1 |

||

| + | |out1 |

||

| + | |outlet position |

||

| + | |- |

||

| + | | |

||

| + | |2 |

||

| + | |out2 |

||

| + | |outlet position |

||

| + | |- |

||

| + | | |

||

| + | |3 |

||

| + | |out3 |

||

| + | |outlet position |

||

| + | |- |

||

| + | | |

||

| + | |4 |

||

| + | |out4 |

||

| + | |outlet position |

||

| + | |- |

||

| + | | |

||

| + | |5 |

||

| + | |Heater |

||

| + | |within the heater |

||

| + | |} |

||

| − | Table 1: Output nodes for the two models |

||

| + | {| class="wikitable" style="margin: auto;" |

||

| − | |||

| + | |+ style="caption-side:bottom;"|''Table 2: Provided files.'' |

||

| − | Model Number Code Comment |

||

| + | |- |

||

| − | Flow Meter 1 out1 outlet position |

||

| + | |Model |

||

| − | 2 out2 outlet position |

||

| + | |Fluid Speed (m/s) |

||

| − | 3 SenL left sensor position |

||

| + | |Link |

||

| − | 4 Heater within the heater |

||

| + | |Size |

||

| − | 5 SenR right sensor position |

||

| + | |- |

||

| − | |||

| + | |Flow Meter |

||

| − | cooling Structure 1 out1 outlet position |

||

| + | |<math>0</math> |

||

| − | 2 out2 outlet position |

||

| + | |[https://portal.uni-freiburg.de/imteksimulation/downloads/benchmark/Convection%20%2838867%29/files/fileinnercontentproxy.2010-02-09.9436538712 flow_meter_model_v0.tgz] |

||

| − | 3 out3 outlet position |

||

| + | |649.4 kB |

||

| − | 4 out4 outlet position |

||

| + | |- |

||

| − | 5 Heater within the heater |

||

| + | | |

||

| + | |<math>0.5</math> |

||

| + | |[https://portal.uni-freiburg.de/imteksimulation/downloads/benchmark/Convection%20%2838867%29/files/fileinnercontentproxy.2010-02-09.9458653965 flow_meter_model_v0.5.tgz] |

||

| + | |757.8 kB |

||

| + | |- |

||

| + | |Cooling Structure |

||

| + | |<math>0</math> |

||

| + | |[https://portal.uni-freiburg.de/imteksimulation/downloads/benchmark/Convection%20%2838867%29/files/fileinnercontentproxy.2010-02-09.9474662166 chip_cooling_model_v0.tgz] |

||

| + | |3.9 MB |

||

| + | |- |

||

| + | | |

||

| + | |<math>0.1</math> |

||

| + | |[https://portal.uni-freiburg.de/imteksimulation/downloads/benchmark/Convection%20%2838867%29/files/fileinnercontentproxy.2010-02-09.9491706281 chip_cooling_model_v0.1.tgz] |

||

| + | |4.0 MB |

||

| + | |} |

||

| + | Further information on the models can be found in <ref name="moosmann2004"/>, |

||

| − | |||

| + | where model reduction by means of the [[wikipedia:Arnoldi_iteration|Arnoldi algorithm]] is also presented. |

||

| − | Table 2: Provided files |

||

| − | |||

| − | |||

| − | Model fluid speed (m/s) Link File Size, Bytes |

||

| − | Flow Meter 0 (File 1) |

||

| − | 664950 |

||

| − | 0.5 (File 2) |

||

| − | 775969 |

||

| − | cooling Structure 0 (File 3) |

||

| − | 4055692 |

||

| − | 0.1 (File 4) |

||

| − | 4159963 |

||

| − | |||

| − | Further information on the models can be found in <ref name="moosmann2004"/> where model reduction by means of the Arnoldi algorithm is also presented. |

||

==References== |

==References== |

||

| Line 88: | Line 146: | ||

<ref name="harper1997">C.A. Harper, <span class="plainlinks">[https://doi.org/10.1036/0071430482 Electronic packaging and interconnection handbook]</span>, New York McGraw- Hill, USA, 1997</ref> |

<ref name="harper1997">C.A. Harper, <span class="plainlinks">[https://doi.org/10.1036/0071430482 Electronic packaging and interconnection handbook]</span>, New York McGraw- Hill, USA, 1997</ref> |

||

| − | <ref name="moosmann2004">C. Moosmann, E.B. Rudnyi, A. Greiner, J.G. Korvink, <span class="plainlinks">[http://modelreduction.com/doc/papers/moosmann04THERMINIC.pdf Model Order Reduction for Linear Convective Thermal Flow]</span>, Proceedings of 10th International Workshops on THERMal INvestigations of ICs and Systems, THERMINIC2004, Sophia Antipolis, France, 2004.</ref> |

+ | <ref name="moosmann2004">C. Moosmann, E.B. Rudnyi, A. Greiner, J.G. Korvink, <span class="plainlinks">[http://modelreduction.com/doc/papers/moosmann04THERMINIC.pdf Model Order Reduction for Linear Convective Thermal Flow]</span>, Proceedings of 10th International Workshops on THERMal INvestigations of ICs and Systems, THERMINIC2004, Sophia Antipolis, France, 2004.</ref> |

| + | |||

| + | <ref name="moosmann2005">C. Moosmann, A. Greiner, <span class="plainlinks">[https://doi.org/10.1007/3-540-27909-1_16 Convective Thermal Flow Problems]</span>,. In: Dimension Reduction of Large-Scale Systems. Springer, Berlin, Heidelberg. Lecture Notes in Computational Science and Engineering, vol 45: 341--343, 2005.</ref> |

||

</references> |

</references> |

||

Revision as of 12:58, 27 February 2018

Note: This page has not been verified by our editors.

Note: This page has not been verified by our editors.

Description

Many thermal problems require simulation of heat exchange between a solid body and a fluid flow. The most elaborate approach to this problem is computational fluid dynamics (CFD). However, CFD is computationally expensive. A popular solution is to exclude the flow completely from the computational domain and to use convection boundary conditions for the solid model. However, caution has to be taken to select the film coefficient.

An intermediate level is to include a flow region with a given velocity profile, that adds convective transport to the model. Compared to convection boundary conditions this approach has the advantage that the film coefficient has not to be specified and that information about the heat profile in the flow can be obtained. A drawback of the method is the greatly increased number of elements needed to perform a physically valid simulation, because the solution accuracy when employing upwind finite element schemes depends on the element size. While this problem still is linear, due to the forced convection, the conductivity matrix changes from a symmetric matrix to an un-symmetric one. So this problem type can be used as a benchmark for problems containing un-symmetric matrices.

Two different designs are tested: a 2D model of an anemometer-like structure mainly consisting of a tube and a small heat source (Fig. 1) [1]. The solid model has been generated and meshed in ANSYS. Triangular PLANE55 elements have been used for meshing and discretizing by the finite element method, resulting in 19282 elements and 9710 nodes. The second design is a 3D model of a chip cooled by forced convection (Fig. 2) [2]. In this case the tetrahedral element type SOLID70 was used, resulting in 107989 elements and 20542 nodes. Since the implementation of the convective term in ANSYS does not allow for definition of the fluid speed on a per element, but on a per region basis, the flow profile has to be approximated by piece-wise step functions. The approximation used for this benchmarks is shown in Figure 1.

The Dirichlet boundary conditions are applied to the original system.

In both models the reference temperature is set to  , Dirichlet boundary conditions as well as initial conditions are set to 0 with respect to the reference.

The specified Dirichlet boundary conditions are in both cases the inlet of the fluid and the outer faces of the solids. Matrices are supplied for the symmetric case (fluid speed is zero; no convection), and the unsymmetric case (with forced convection).

Table 1 shows the output nodes specified for the two benchmarks, Table 2 links the filenames according to the different cases.

, Dirichlet boundary conditions as well as initial conditions are set to 0 with respect to the reference.

The specified Dirichlet boundary conditions are in both cases the inlet of the fluid and the outer faces of the solids. Matrices are supplied for the symmetric case (fluid speed is zero; no convection), and the unsymmetric case (with forced convection).

Table 1 shows the output nodes specified for the two benchmarks, Table 2 links the filenames according to the different cases.

Origin

This benchmark is part of the Oberwolfach Benchmark Collection[3]; No. 38867, see [4].

Data

Matrices are in the Matrix Market format. The matrix name is used as an extension of the matrix file. *.C.names contains a list of ouput names written consecutively. The system matrices have been extracted from ANSYS models by means of mor4fem.

| Model | Number | Code | Comment |

| Flow Meter | 1 | out1 | outlet position |

| 2 | out2 | outlet position | |

| 3 | SenL | left sensor position | |

| 4 | Heater | within the heater | |

| 5 | SenR | right sensor position | |

| Cooling Structure | 1 | out1 | outlet position |

| 2 | out2 | outlet position | |

| 3 | out3 | outlet position | |

| 4 | out4 | outlet position | |

| 5 | Heater | within the heater |

| Model | Fluid Speed (m/s) | Link | Size |

| Flow Meter |

|

flow_meter_model_v0.tgz | 649.4 kB |

|

flow_meter_model_v0.5.tgz | 757.8 kB | |

| Cooling Structure |

|

chip_cooling_model_v0.tgz | 3.9 MB |

|

chip_cooling_model_v0.1.tgz | 4.0 MB |

Further information on the models can be found in [5], where model reduction by means of the Arnoldi algorithm is also presented.

References

- ↑ H. Ernst, High-Resolution Thermal Measurements in Fluids, PhD thesis, University of Freiburg, Germany, 2001.

- ↑ C.A. Harper, Electronic packaging and interconnection handbook, New York McGraw- Hill, USA, 1997

- ↑ J.G. Korvink, E.B. Rudnyi, Oberwolfach Benchmark Collection, Dimension Reduction of Large-Scale Systems, Lecture Notes in Computational Science and Engineering, vol 45: 311--315, 2005.

- ↑ C. Moosmann, A. Greiner, Convective Thermal Flow Problems,. In: Dimension Reduction of Large-Scale Systems. Springer, Berlin, Heidelberg. Lecture Notes in Computational Science and Engineering, vol 45: 341--343, 2005.

- ↑ C. Moosmann, E.B. Rudnyi, A. Greiner, J.G. Korvink, Model Order Reduction for Linear Convective Thermal Flow, Proceedings of 10th International Workshops on THERMal INvestigations of ICs and Systems, THERMINIC2004, Sophia Antipolis, France, 2004.