Note: This page has not been verified by our editors.

Note: This page has not been verified by our editors.

1 Description

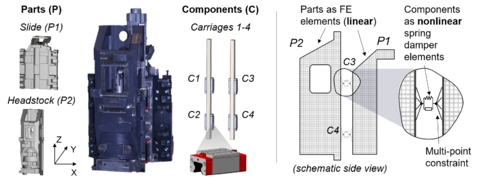

The Feed axis benchmark is a thermo-mechanical model of a subassembly of a modern 5-axis vertical milling machine described in[1]. Due to trade secrets the model provided here uses a coarser discretization and sliqhtly different material properties. The system consists of two large structural parts, namely the slide and the headstock, and four machine components which are the carriages, see Figure 1. During the finite element analysis, the parts are modeled as linear elements, while the components are considered as nonlinear spring-damper elements using multi-point constraints. The temperature change in the guideway systems of a machine tool can lead to a measurable change in the static stiffness and causes a nonlinearity in the model. Thus, the stiffness matrix has a small nonlinear part reflecting these geometrically local nonlinearities.

2 Dimensions

System structure:

\[ \begin{align} E \dot{x}(t) + K x(t) &= B u(t), \\ y(t) &= C x(t) \end{align} \]

System dimensions\[E \in \mathbb{R}^{n \times n}\], \(K \in \mathbb{R}^{n \times n}\), \(B \in \mathbb{R}^{n \times m}\), \(C \in \mathbb{R}^{p \times n}\), with \(n=79\,814\), \(m=20\) and \(p=63\).

3 Data

The data is available at Zenodo. It contains information for 6 different poses of the model which can be combined in form of a switched system to consider a relative movement between slide and headstock.

4 Remarks

- The finite element discretization has been performed with Ansys.

- The system consists of a large linear part and a small nonlinear subsystem. A strategy for MOR by substructuring allowing the usage of standard methods for LTI systems is presented in[1].

- It is a differential-algebraic system with one-sided coupling.

- Further investigations on MOR for this benchmark including the problem of moving loads modeled in form of a switched system can be found in[2]. Here, the scaling of the model plays an important role.

- The data package[3] also provides codes for MOR and simulation of the model.

5 Origin

The Feed axis model was developed in the CRC/TR 96 Project-ID 174223256 financed by the German Research Foundation DFG.

6 Citation

To cite this benchmark, use the following references:

- For the benchmark itself and its data:

@misc{dataVS22,

author = {J. Vettermann and A. Steinert and J. Saak},

title = {Feed axis},

howpublished = {hosted at {MORwiki} -- Model Order Reduction Wiki},

year = 2022,

doi = {10.5281/zenodo.6778458}

}

- For the background on the benchmark:

@article{VS22,

author = {J. Vettermann and A. Steinert and C. Brecher and P. Benner and J. Saak},

title = {Compact thermo-mechanical models for the fast simulation of machine tools with nonlinear component behavior},

journal = {at - Automatisierungstechnik},

volume = 70,

number = 8,

year = 2022,

pages = {692--704},

doi = {10.1515/auto-2022-0029},

}

7 References

- ↑ 1.0 1.1 1.2 J. Vettermann, A. Steinert, C. Brecher, P. Benner, J. Saak. "Compact thermo-mechanical models for the fast simulation of machinetools with nonlinear component behavior", at - Automatisierungstechnik, 70(8): 692–704, 2022.

- ↑ Q. Aumann, P. Benner, J. Saak, J. Vettermann. "Model order reduction via substructuring for a nonlinear, differential-algebraic machine tool model with moving loads", Proceedings in Applied Mathematics and Mechanics, 93(1), 2023.

- ↑ J. Vettermann, A. Steinert, J. Saak. Code and Data for Numerical Experiments in "Compact Thermo-Mechanical Models for the Fast Simulation of Machine Tools with Nonlinear Component Behavior", zenodo, 2022.